August 26, 2011

Another sneak preview. After many years of using PIAA lights, (www.piaa.com), the choice was easy when we were designing our Buckstop Bumper, (www.buckstop.biz), for The Turtle V. The all-new PIAA RS 600 Shock Lamp H.I.D. Long Range Driving Light has an internal ballast. It has a black polyamide and fiberglass housing, and the polycarbonate clear-coat lens protects the multi-surface reflector PIAA is famous for. As with all PIAA lights on The Turtle III and The Turtle IV, the housing mount is rock-solid yet easy to adjust. For a wide-angle fog light, we chose the 510 Series Xtreme White SMR Fog with the upgraded 110-watt XTRA Xtreme White Plus bulb. Its 60° spread will light up the sides of those dark Baja backroads. The main light bar was specifically designed to allow access to the Warn 16.5 winch, (www.warn.com), shown here with its locking cover in place.

August 26, 2011

Hi everyone:

We’ve changed our Blog Postings slightly. You will now receive a teaser via email. If you want to read the whole Blog and view the Ph0tos, all you need to do is click on the (blue) title which brings you directly to the complete blog on The Turtle Expedition page.

Happy Travels! Monika

August 24, 2011

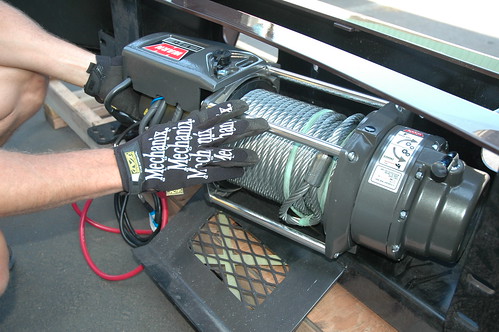

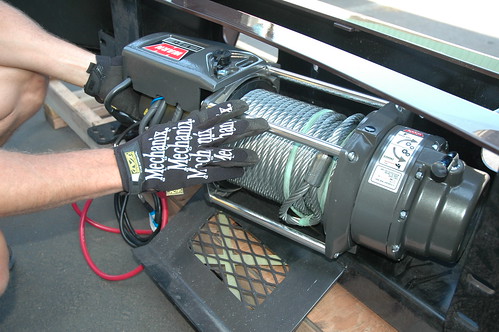

As final assembly of our new Buckstop Bumper for The Turtle V continues, a Warn 16.5ti electric winch was installed. www.warn.com The frame of the Buckstop Outback Bumper was configured specifically for the Warn 16.5. This is the highest capacity, most technologically advanced winch for big trucks. The Gen II series wound motor combined with a 3-stage planetary gear train delivers 16,500 lbs. of pulling power. Thermometric indicator LED provides operator feedback on motor temperature.

The ninety feet of 7/16 steel cable will be replaced with 100-125 feet of Viking Dyneema® synthetic winchline which is up to 15 times stronger than quality steel. Caution must be used when making a side pull that the added line capacity does not bunch up on one side of the drum and damage the cross bars. www.vikingoffroad.com. We will also swap out the factory fairlead rollers with Viking Delrin rollers, designed to be used with synthetic winch lines, replacing the factory galvanized parts.

August 15, 2011

As final modifications were made to the new Buckstop bumper for The Turtle V, Gabriel Arreola used a plasma cutter to trim off the wing tips to match the flares of the front wheel wells. We robbed the rock guard that protects the power steering cooler and adapted it to the new bumper. Factory tie-down loops were drilled out and attached with grade-8 bolts to the main bumper frame. Powder coating is next.

August 10, 2011

As the details of our new Buckstop Heavy Duty Bumper for The Turtle V took shape, practical ideas from previous designs merged. Of course, we added 2” receivers on both sides, off-set so when we are pushing a trailer into a tight place, the driver can see where it’s going.

Dual receivers open the possibility of mounting other equipment including a motorcycle as we did on The Turtle II. https://www.turtleexpedition.com/vehicles/the-turtle-ii/

A drawtube lock-bolt welded on the bottom of each receiver will take out any slack or wiggle. Thin vertical bars welded in front of the headlights will keep most branches at bay. Taking a concept from Paul Rickard, Buckstop designed large locking water and dust proof storage boxes on each side. We guess you may be wondering how this new bumper will look. We are too!

August 8, 2011

Working with Dorian Hartfield, owner of Buckstop, and his chief fabricator, Gabriel Arreola, the process of hand-carving our custom Buckstop bumper for The Turtle V began with the design of cross bars and a light bar. This is the frame around the picture, so both function and great looks were equally important. Tube bending is an art. Achieving two identical parts with multiple curves is not easy. The light bar needed to blend with the overall shape, securely hold powerful driving lights, and not block access to our Warn 16.5 winch. As the shapes began to merge, we knew we were on the right track. Careful measurements taken off the truck’s grill, headlights and turn signals were fed into the Buckstop CAD program to maximize form and function.

August 5, 2011

I posted 5 photos on Facebook in the album “Two Turtles at the Overland Expo 2011” http://fb.me/ZiUAiYCU

August 5, 2011

After studying the designs of our last nine bumpers, we realized that the upright support bars needed be at an angle that would push large animals like deer, cows and burros away from the truck, not up into the windshield. The basic shape of the Buckstop Outback was a good compromise. The welded box design is very strong and lighter than a thick piece of solid steel. With the bumper’s foundation pre-fitted, the real fun could begin. How could we blend our own 38 years of experience with ideas taken from our original Land Rover’s “Tumba Burro”, Australian “Roo-Bars”, Paul Richard Engineering, Kendall Engineering and now Buckstop to achieve the goals of strength, aesthetics and function? Stay tuned for more.

August 2, 2011

While the Reunel bumper on The Turtle V had served its purpose, it had always lacked the really functional elements that the custom Rickard Engineering Compartment Bumpers on The Turtle III & Turtle IV used. Paul Rickard died a few years ago, and his mastery of engineering and design was a great loss to those whose passion is exploring the backroads of the world.

There are plenty of “cookie cutter” mass-produced bumpers on the market, but few companies have the flexibility to include the refinements we wanted. Buckstop Truckware in Newberg, OR (www.buckstop.biz) took the challenge. After uncountable CAD drawings, more than a few emails, and over a year of looking at the possibilities, it was time to make a move. The first step was to unbolt the old bumper from The Turtle V.

July 31, 2011

When we originally designed The Tortuga Expedition Camper, we installed a microwave oven. In real life on the road, we used it only occasionally to reheat coffee or a bowl of soup. Since propane is the best way to cook, and it is readily available everywhere in the world, the microwave was really an unneeded luxury. The hole it was using was taking up a large valuable storage space. Jeff Paddock at Nautilus, (www.nautilusconstruction.com), in La Pine, OR put his amazing custom cabinet making skills to work, and we quickly had two very useable shelves with dual grain-matched cherry-wood doors that close with secure marine-quality latches. The beautiful cherry will soon darken to blend with the other cabinets.