Across the USA #7 (Rickson Truck Wheels)

Leaving the Espar Headquarters in Mississauga, Ontario, we headed south towards New York State. Crossing the Rainbow Bridge we snapped a picture of Niagara Falls and it occurred to me that we were not “traveling”. This was just “driving”. Our typical travel day might only involve 150 miles and maybe 4 or 5 hours on the road before we find a nice place to stop for the night. If it’s really nice, why not stay a day or two and explore the area?

Crossing the border into Pennsylvania,— “Speed Limit 55 mph”, “Please Wear Your Seatbelt for the Next Million Miles”, but everyone’s going 78 mph and tailgating like they do in Los Angeles, —our next stop was Rickson Truck Wheels in Hunt Valley, Maryland.

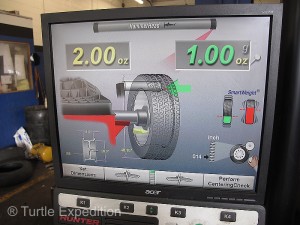

Very few shops in our area of California have tire-balancing machines that can handle our big Michelin XZL MPT 41-inch tires. More importantly, it’s not just having the right machine. Someone needs to know how to use it. While the ideal way to balance these big tires on new rims would have been finding a high point on the wheel first, then finding a high point on the tire and then matching the two so that they cancel each other. There was no time for that. Using a sophisticated computerized Hunter Hammerhead balancing machine with the proper centering device for our 20” wheels, coupled with Dan Rickson’s knowledge of how to use that machine, was the next best thing.

In some cases we were able to remove five weights and replace them with two, following the laser line that the Hunter Hammerhead drew across the tire. In two cases, after the Hunter found a high spot on the combination of tire and wheel, we did spin the tire on the rim to compensate. These are big tires and Rickson wheels weigh something like 130 pounds each. The slight shimmy we had been noticing at 65 mph is now gone.

While we were at the Rickson factory, Dan gave us a quick tour. We got to see the Mercedes blanks that were the foundation for our wheels. We asked Dan why he didn’t put valve stems on both sides of our reversible wheels. Basically he said it wouldn’t be DOT approved. We had consulted with Steve Sasaki at Powertank and with the people at GH Meiser (Accu-Gage Tire Gauge). Both agreed that it was not a problem to simply drill a hole on the backside of the wheel and add another valve stem. The surface where the stem sits does not have to be flat. The actual seal is created as the rubber expands inside the hole when the nut on the valve stem is tightened.

Back in California, we had experimented using 90° extensions on the valve stems. That was not the answer, so we had to drill holes and add valve stems after we had already mounted the tires. It was much more difficult, but we had no choice. Because we air our tires up and down frequently, depending on road conditions, and because the rims are reversible, valve stems on both sides were a necessity.

Dan Rickson knew how to take every advantage of the sophisticated Hunter Hammerhead balancing machine.

In some cases we were able to remove as many as five weights and replace them with two, following the specific instructions given by the Hunter Hammerhead.

Steel blanks like these are ordered from Mercedes. They are the foundation for custom wheels like ours. Hub-centric holes and lug nut holes are machined in the blanks.

The specialty of Rickson Truck Wheels is a much stronger replacement 19.5″ rim for those that typically come on trucks and motor homes today.

Leave a Comment